Laying the Keel

A ship’s construction officially starts with laying the keel — the spine of the ship. This is as true for a full-sized ship built in a dry dock as it is with a model ship on a workshop table. The real SS Christopher Columbus had its keel laid in 1892 in Superior, Wisconsin by the American Steel Barge Company. The 1:80 scale Columbus had its keel laid on September 26 of 2025 in Rochester, Minnesota.

Prior to that date, digital work began by creating the hull in CAD software to make early progress on some of the reconstruction and engineering. The model of the Columbus is being constructed with a false keel and ribs made of 5mm plywood. Ribs are spaced equally throughout the length of the ship and make up the general shape of the hull. The plywood was then cut using my xTool laser cutter (my favorite shop tool).

The hull as designed in Fusion 360 before being sent to the laser cutter.

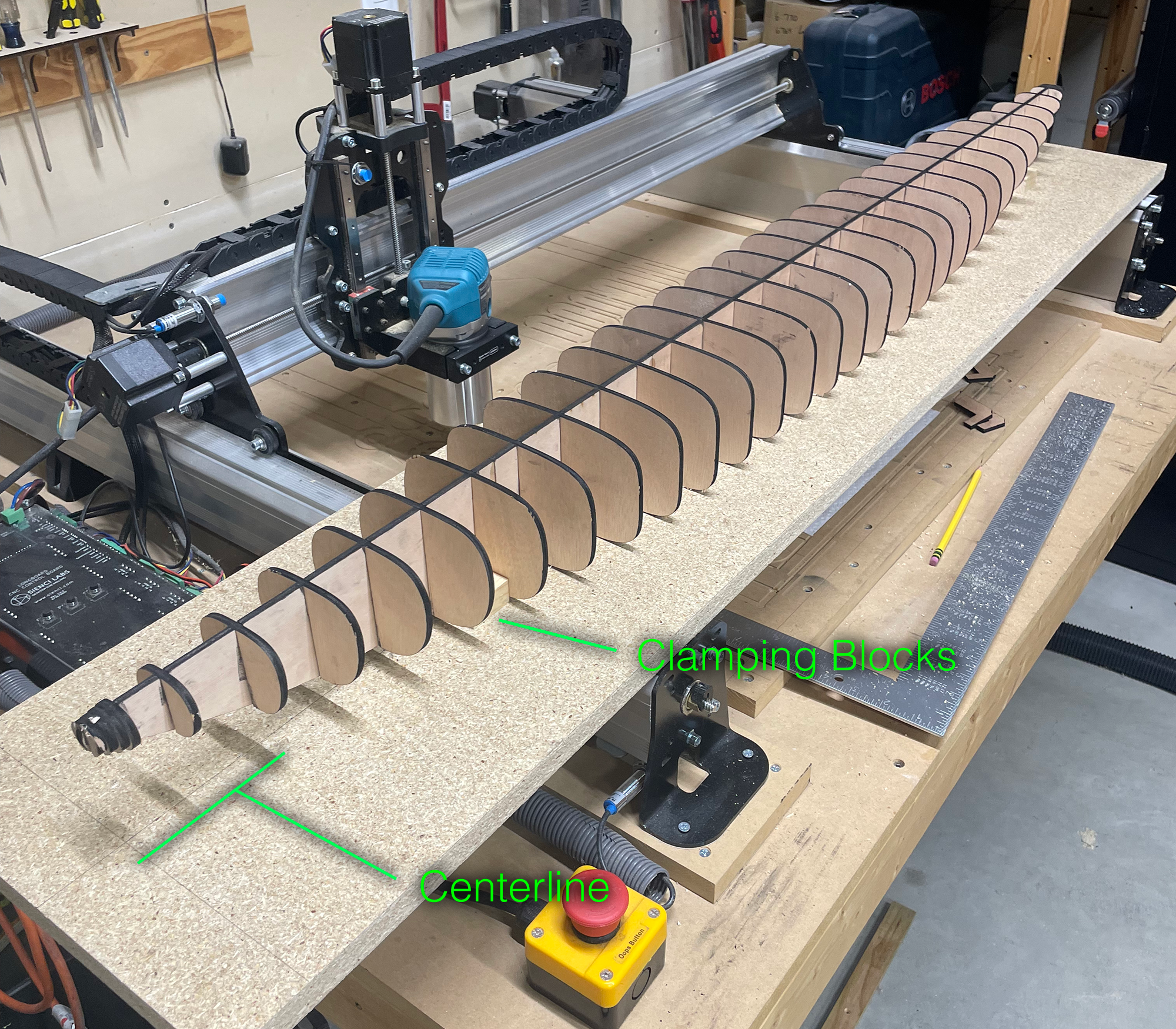

For wooden model ships like this one, it is imperative that the keel be kept perfectly straight during initial construction of the hull. Without this crucial step, the subsequent steps of the build will be negatively impacted by compounding errors. In the photo below, you can see the jig that was used to maintain alignment to a centerline. The keel is clamped about every fifth rib with scrap wood blocks to maintain its straightness along the full length. Each rib is then glued and clamped at precise right angles from the keel using 1-2-3 machine blocks. Investment in precision for this step means that the hull will be both straight and symmetric.

A simple jig to maintain keel alignment to a centerline.